The rotary lobe pump shaft may break during running, and we generally think that it is due to poor shaft material. In practice, more robust material is vital but not a critical factor; we must find out the cause and solve it.

Poor Material

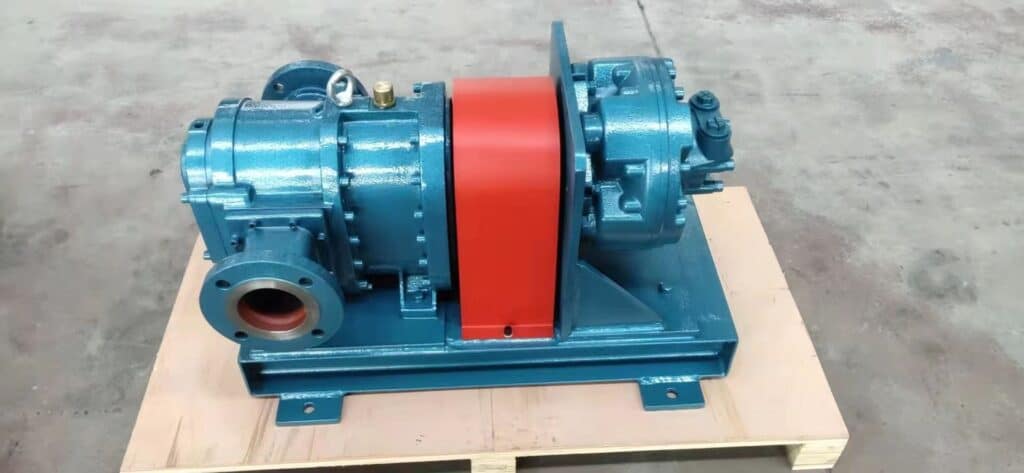

Choose a reliable rotary lobe pump manufacture, Yaness build shaft by 42CrMo4 (ASTM4140) steel.

Excessive Pressure

Do not run the pump out of working range.

Pump Vibration

Stop the pump and solve the vibration.

High Speed

Slow the speed; the operating speed of most rotary lobe pumps is 50-650rpm.

Improper Installation

Check the orientation of the coupling before start-up and then every 2000 operating hours (at least once a year) and correct it.

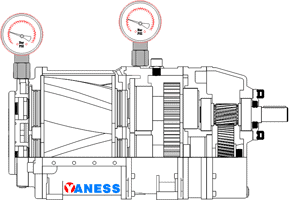

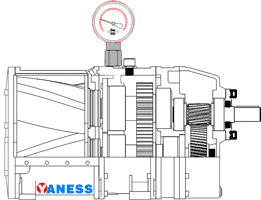

Yaness designed a fully supported shaft with inboard and outboard bearings to avoid the pump shaft breaking, so both sides of the shafts are fully supported.