Ever wondered what sets Yaness rotary lobe pumps apart? I’m Carl Lopez, and after 12 years in the pump industry, I can tell you it’s our unique built-in reduction gear. Let’s explore how this feature makes our pumps superior.

Introduction to Yaness Rotary Lobe Pumps

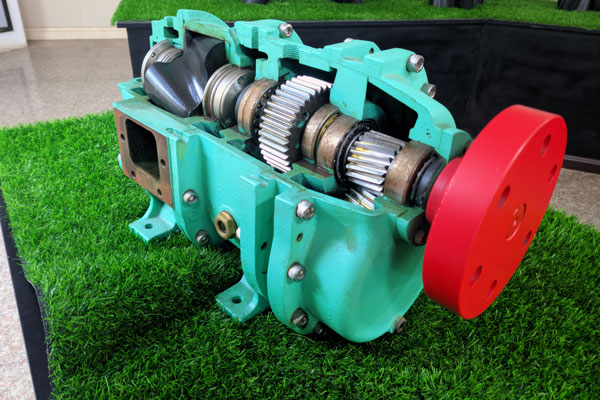

Rotary lobe pumps are crucial for handling high-viscosity fluids in various industries. At Yaness, our innovative design includes a built-in reduction gear, which offers significant advantages over competitors like Boerger, Vogelsang, and LobePro. Visit Yaness Rotary Lobe Pump Parts for more information.

Understanding Synchronization and Reduction Gears

Synchronization Gears

Synchronization gears in our pumps ensure that the lobes rotate harmoniously without making contact, maintaining the pump’s integrity and fluid quality.

Reduction Gears

Reduction gears reduce the motor’s speed to a manageable level, minimizing wear and tear and enhancing the pump’s lifespan and efficiency. This is a crucial feature in our pumps, as detailed in our working principles of rotary lobe pumps.

The Yaness Advantage: Built-in Reduction Gear

Unlike our competitors, Yaness rotary lobe pumps feature a built-in reduction gear, providing distinct advantages:

Space Efficiency

Our built-in reduction gear eliminates the need for an external gear motor, saving valuable installation space. This is particularly beneficial in confined spaces where every inch counts.

Cost Reduction

Integrating the reduction gear into the pump reduces the overall system cost, making Yaness pumps more economical. Customers save on the need for an external gear motor.

Simplified Installation

With fewer components to install and align, our built-in reduction gear simplifies the installation process, reducing setup time. This is a key benefit for industries looking for efficiency and reliability.

For more details, visit our page on the advantages of Yaness rotary lobe pumps.

Practical Applications of Built-in Reduction Gear

Oil and Gas Industry

In the oil and gas industry, where space and reliability are critical, our built-in reduction gear ensures efficient operation and space savings.

Chemical Processing

For chemical processing applications, the reduction gear provides precise control over pump speed, ensuring consistent handling of various chemicals.

Food and Beverage Industry

The space-saving design and cost efficiency make our pumps ideal for the food and beverage industry, helping manufacturers optimize their production lines. For more information, see our rotary lobe pumps in the food and beverage industry.

Maintenance and Troubleshooting

While the built-in reduction gear simplifies the system, regular maintenance is essential for optimal performance:

Regular Lubrication

Proper lubrication reduces friction and wear on the gears, ensuring smooth operation. Regularly check and top up the gearbox oil as needed.

Routine Inspections

Conduct routine inspections to identify signs of wear or damage early, preventing costly breakdowns.

Alignment Checks

Ensure that the gearbox is correctly aligned with the motor and the pump to avoid unnecessary strain and wear. For detailed tips, refer to our maintenance tips for rotary lobe pumps.

For a deeper understanding of the gearbox’s role, check out our article on the role of a gearbox in a lobe pump.

Conclusion:

The built-in reduction gear in Yaness rotary lobe pumps sets us apart from the competition by saving space, reducing costs, and simplifying installation. Understanding this unique feature can help you make an informed decision when selecting the right pump for your application.