How Yaness’s Built-in Reduction Gear Revolutionizes Rotary Lobe Pumps

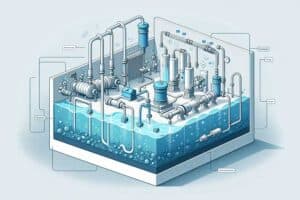

Yaness rotary lobe pumps feature a built-in reduction gear, saving space and reducing costs. Learn how this innovative feature benefits various industries and simplifies maintenance.