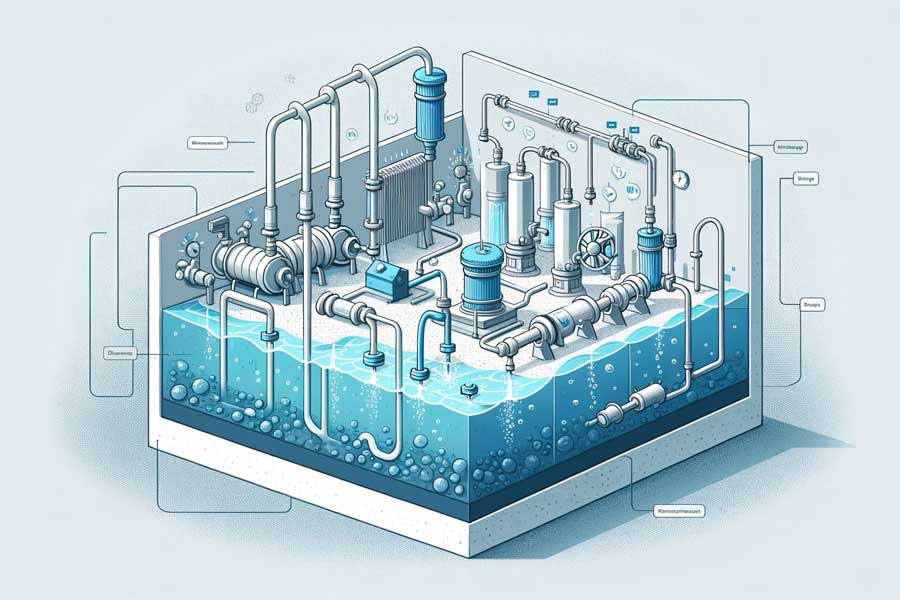

Membrane Bioreactor (MBR) technology represents a significant advancement in wastewater treatment, combining conventional biological degradation with membrane filtration to provide high-quality effluent. An essential component of optimizing these systems is selecting the right type of pump. مضخات الفص, known for their efficiency and reliability, play a crucial role in enhancing the overall performance of MBR systems.

فهم مضخات الفص

Lobe pumps are positive displacement pumps designed to handle viscous fluids, slurries, pastes, and a variety of other liquids. These pumps are particularly well-suited for applications requiring precise volume metering and gentle handling of the product, which are critical in MBR systems. The main features that make lobe pumps ideal for MBR include their non-contacting rotary lobes, which minimize shear and abrasion, providing consistent flow and reducing the risk of damaging sensitive membrane components. Learn more about the principles of lobe pumps.

Advantages of Using Lobe Pumps in MBR Systems

Enhanced Process Stability

Lobe pumps deliver a continuous, pulsation-free flow that is vital for maintaining the stability of the biological process in MBR systems. Their ability to handle varying flow rates without losing efficiency ensures that the biological components of the MBR are consistently supported under all operational conditions.

Improved Sludge Handling

MBR systems often deal with high-viscosity fluids, including heavy sludges. Lobe pumps are specifically designed to handle such materials effectively, reducing the likelihood of clogs and maintenance issues, which are common with other types of pumps. For insights into handling difficult fluids, see our article on مضخات فصية للمياه القذرة والزيت.

انخفاض استهلاك الطاقة

One of the significant advantages of lobe pumps in MBR applications is their energy efficiency. By providing a consistent flow at lower speeds, lobe pumps reduce power consumption, which is crucial for keeping operational costs down in wastewater treatment facilities. Discover how energy efficiency is impacted by the use of lobe pumps.

Operational Insights

Installation Considerations

Integrating lobe pumps into an MBR system requires understanding both the technical specifications and the environmental conditions of the installation site. It’s important to consider factors such as the chemical compatibility of materials and the physical configuration of the pump setup to ensure optimal performance and ease of maintenance.

Maintenance and Durability

Lobe pumps are designed for easy maintenance, featuring external bearing designs and simple construction that allow for quick repairs without significant downtime. Regular maintenance ensures that these pumps can operate for extended periods, even under the harsh conditions typical of MBR systems. Learn more about our maintenance services.

Case Studies

Small-Scale Applications

In small municipal wastewater treatment facilities, lobe pumps have been shown to significantly improve the efficiency and reliability of MBR systems. These applications demonstrate the pump’s ability to adapt to different scales of operation with minimal adjustment.

Large-Scale Industrial Use

Large industries benefit from using lobe pumps in their MBR systems by achieving more stable wastewater treatment processes, which are crucial for meeting regulatory standards and maintaining production efficiency.

Choosing the Right Lobe Pump for Your MBR System

Selecting the right lobe pump involves considering a range of factors, including the fluid characteristics, the required flow rate, and the operational pressure. Additionally, customization options such as the choice of lobe material and seal types can be tailored to meet specific needs and applications. Explore our customization options.

خاتمة

The use of lobe pumps in MBR systems is a game-changer for many industries, offering significant improvements in process stability, energy efficiency, and operational costs. By choosing the right lobe pump, facilities can enhance their wastewater treatment processes and ensure long-term, reliable performance.

For expert advice on selecting and integrating lobe pumps into your MBR system, or to request a quote, don’t hesitate to contact us.

Frequently Asked Questions (FAQ)

Q: What are the primary benefits of using a lobe pump in an MBR system?

A: Lobe pumps offer superior handling of viscous fluids, reduced energy consumption, and improved process stability, making them ideal for MBR applications.

Q: How do lobe pumps contribute to energy efficiency in MBR processes?

A: Their ability to operate efficiently at low rotational speeds minimizes energy costs and enhances overall

system sustainability.

Q: What maintenance is required for lobe pumps in harsh MBR environments?

A: Regular maintenance, including routine inspections and component replacements, ensures optimal performance and longevity of lobe pumps in tough conditions.

Q: Can lobe pumps handle high-viscosity fluids found in some MBR applications?

A: Yes, lobe pumps are specifically designed to handle high-viscosity fluids effectively, making them perfect for sludge and other challenging MBR applications.

Q: How do I choose the right lobe pump model for my specific MBR needs?

A: Consider the fluid’s properties, required flow rates, and environmental factors when selecting a lobe pump, and explore customization options to tailor the pump to your specific requirements.