مضخات الفص المغلفة بالمطاط هي الأبطال المجهولين للتعامل مع السوائل-يمكن التقيد بهم ، قابلين للتكيف. ولكن حتى أفضل المضخات يمكن أن تكون منخفضة الأداء إذا لم يتم طلب سرعتها في اليمين. سواء كنت تنقل ملاط الشوكولاتة أو مياه الصرف الصحي الكاشطة ، فإن تسمير دورة في الدقيقة المثالية يعني كفاءة أفضل ، وأقل ارتداء ، وعدد أقل من الصداع. دعنا نقسم كيفية إتقان هذا التعديل الحرج.

إن ضبط سرعة مضخة الفص لا يتعلق فقط بتشغيل المقابض - إنه فعل موازنة بين شخصية السائل الخاصة بك ، ومتطلبات النظام ، وخيارات محرك الأقراص الذكية. تخطئ ، وقد تكون مغازلة مع التجويف أو التآكل المبكر ؛ احصل عليه بشكل صحيح ، ومضخةك مثل المحرك المضبوط جيدًا.

الآن ، إليك كيكر: لا يوجد حل واحد يناسب الجميع. من مخفضات التروس الصديقة للميزانية إلى التكنولوجيا الفائقة VFDs، أفضل رهانك يعتمد على إيقاع عمليتك. دعنا نستكشف لماذا ، كيف ، و "ما الذي يعمل أين" للتحكم في السرعة.

العلم وراء تعديل السرعة (ولماذا يهم)

فكر في سرعة المضخة مثل وتيرة عداء الماراثون. ادفع بشدة (RPM عالية) ، والفصوص المطاطية المغطاة بالارتباك مثل العضلات المنهكة. اذهب بطيئًا جدًا ، ولن تصل أبدًا إلى أهداف معدل التدفق. البقعة الحلوة؟ حيث تلبي الكفاءة طول العمر.

التجويف هو القاتل الصامت لمضخات الفص - تلك الفقاعات الصغيرة من تغييرات الضغط السريع تآكل الفصوص بشكل أسرع من ورق الصنفرة. التحكم السليم في السرعة يبقي هذا الخطر في الخليج.

خذ مضخات من الدرجة الغذائية التي تتعامل مع معجون الطماطم: عند 600 دورة في الدقيقة ، تحول قوة القص معجونك الممتاز إلى خيبة أمل مائية. انخفض إلى 400 دورة في الدقيقة مع مخفض للعتاد ، وتحافظ على الملمس أثناء قطع استخدام الطاقة بنسبة 18 ٪ (استنادًا إلى 2023 F&B تقرير كفاءة المضخة).

العثور على بقعة المضخة الحلوة: دليل خطوة بخطوة

ابدأ بلعب المباحث مع طلبك:

- ما هو الخاص بك لزوجة السائل؟ (يشبه العسل؟ ماء؟)

- أي حساسية درجة الحرارة؟

- معدل التدفق المطلوب؟

نصيحة للمحترفين: إزاحة المضخة × RPM الهدف = معدل التدفق النظري. لكن العوامل في العالم الحقيقي مثل "الانزلاق" (الفصوص المتسللة السوائل) تعني أن التدفق الفعلي عادة ما يكون أقل من 5 إلى 15 ٪.

إليك مثال في العالم الحقيقي من عميل يانيس:

- هدف: نقل 60 لتر/دقيقة من كريم مستحضرات التجميل (اللزوجة: 8000 CP)

- الإزاحة المضخة: 0.12 L / Rev

- الرياضيات: 60 ÷ 0.12 = 500 دورة في الدقيقة

- الواقع: أضيفت 10 ٪ من المخزن المؤقت للزلزان → تعيين إلى 550 دورة في الدقيقة

5 طرق مثبتة للتحكم في دورة في الدقيقة (ومتى تستخدمها)

من ميكانيكا المدرسة القديمة إلى السحرة الرقمية ، إليك مجموعة الأدوات الخاصة بك:

مخفضات التروس المدمجة هي حل "تعيينها ونسيانها" ، بينما تتألق VFDs في العمليات الديناميكية التي تحتاج إلى تعديلات في الوقت الفعلي. لكن لا تغفل عن محركات العتاد أو المخفضات الخارجية - إنها سكاكين الجيش السويسري للسيطرة على السرعة.

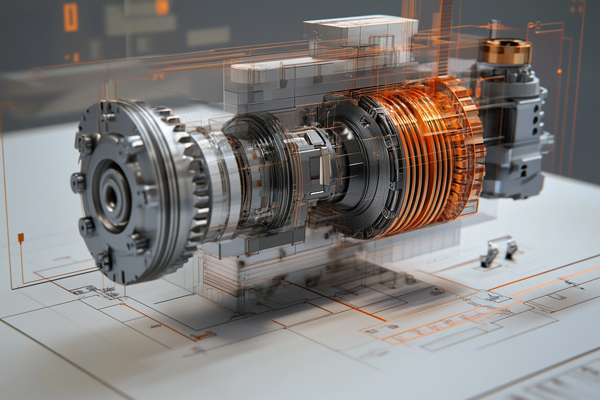

1. مخفضات التروس المدمجة: فرس العمل لتوفير الفضاء

- كيف تعمل: صفعات علبة تروس للحد من السرعة مباشرة على المضخة. إقران محرك قياسي 1450 دورة في الدقيقة مع مخفض 3: 1؟ أنت الآن تضخ 483 دورة في الدقيقة.

- يانيس حافة: 30 ٪ أرخص من المخفضات الخارجية ، يناسب المساحات الضيقة.

- الأفضل ل: المصانع التي تعمل 24/7 بسرعات ثابتة (على سبيل المثال ، ضخ زيوت التشحيم عند 460 دورة في الدقيقة).

2. VFDS: الفنان الدقيق

- بقعة حلوة: عمليات الدُفعات حيث تتغير السرعة كل ساعة (على سبيل المثال ، تخمير - slow للهروس ، سريع للتحويلات).

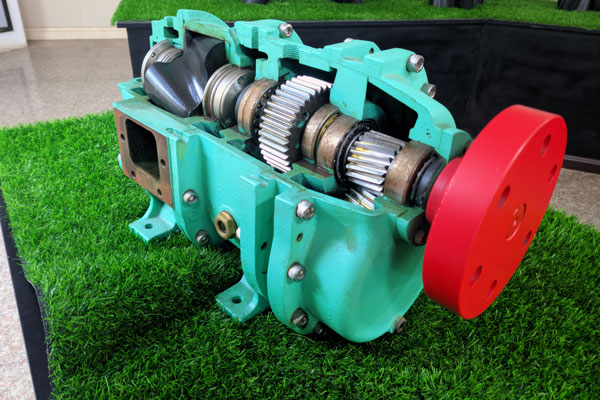

3. محركات العتاد: قوة الكل في واحد

- كيف تعمل: محرك مع تروس متكاملة (على سبيل المثال ، حلزوني ، دودة) التي توفر انخفاض السرعة المسبق. هل تحتاج إلى 530 دورة في الدقيقة؟ احصل على محرك 1450 دورة في الدقيقة مع علبة تروس 2.75: 1.

- للنصيحة: يانيس يوفر نماذج تصنيف IP65 لبيئات الغسيل-مثالية لنباتات الطعام.

- التنازل عن ميزة ممن أجل الحصول على أخرى: أكبر قليلاً من المحركات المستقلة ولكنه يلغي الصداع المحاذاة.

4. مخفضات التروس الخارجية: الأرض الوسطى المرنة

- لماذا تختار: هل تريد إعادة استخدام المحركات الحالية ولكن تحتاج إلى نسب مخصصة؟ الترباس على مخفض خارجي.

- فحص الواقع: يأكلون مساحة الأرض ويكلفون 20-40 ٪ أكثر من الإصدارات المدمجة. الأفضل لإعادة تحديث الأنظمة القديمة.

5. المحركات الهيدروليكية: الرافع الثقيل

- متى تختار: هل تحتاج إلى عزم دوران ضخم للحمأة السميكة؟ يستحق متاعب النظام الهيدروليكي.

مخفضات مدمجة مقابل الخيارات الخارجية: دليل قرار مدته 30 ثانية

✅ اختر يانيس مدمج إذا ...

- يتم إصلاح احتياجات السرعة الخاصة بك (على سبيل المثال ، 530 دورة في الدقيقة في اليوم ، يوم خارج)

- مساحة الأرضية أكثر تشددًا من غرفة محرك الغواصة

- قواعد الميزانية على المرونة المستقبلية

🛠 اذهب خارجي/محرك ترس إذا ...

- أنت تعديل المضخات القديمة وتريد الحفاظ على المحركات

- قد تحتاج إلى تغييرات نسبة أسفل الخط (خارجي = التروس القابلة للتبديل)

- يمكن تحمل علاوة تكلفة بنسبة 15 ٪ على النموذج

المخفضات المدمجة مقابل VFDS: smackdown التكلفة

دعونا نستقر على هذا مثل المهندسين - بأرقام باردة وصعبة:

| عامل | مخفض الترس المدمج | VFD |

|---|---|---|

| التكلفة المقدمة | 50 دولار-1000 دولار | 1500 دولار-10،000 دولار |

| وفورات الطاقة | قليل | ما يصل إلى 25 ٪ |

| مرونة السرعة | مُثَبَّت | لانهائي |

| صيانة | تقريبا الصفر | شيكات الإلكترونيات |

قاعدة الإبهام: إذا كانت عمليتك هي قطاع الاتساق ، فاختر مخفضات التروس. إذا كان ذلك عبارة عن ارتجال موسيقى الجاز ، فانتقل إلى VFD.

دراسة الحالة: عميل مخفض اليانيس في تصنيع الورق:

- مشكلة: مطلوب لخفض مستوى محركات 1450 دورة في الدقيقة إلى 530 دورة في الدقيقة لنقل اللب.

- حل: مثبتات مدمجة 2.75: 1 المخفضات.

- نتيجة: تعديلات سرعة الصفر اللازمة لمدة عامين ، و 40 ٪ من التكلفة المقدمة مقابل VFDs.

3 أخطاء تعديل السرعة التي ستكلفك

تعلم من أخطاء الآخرين - هذه الأخطاء أكثر شيوعًا مما تعتقد:

الخطأ رقم 1: سرعة التحريك إلى "تعويض" التدفق المنخفض. النتيجة: الفصوص المذابة في 3 أشهر.

الخطأ رقم 2: تجاهل شخصية السائل. النتيجة: تتجه سوائل حساسة القص إلى الهريسة.

الخطأ رقم 3: نسيان تأثير الدومينو. النتيجة: صراخ المحامل ، وتسرب الأختام ، وترتفع وقت التوقف.

🧨 خطأ #1: الإغراء الزائد

"مجرد صدمها إلى 600 دورة في الدقيقة - نحتاج إلى ضرب الحصة!"

- ماذا يحدث: ارتفاع درجة حرارة الطلاء المطاطي (>80 درجة مئوية) ، وفقدان المرونة. الفصوص المشوهات ، وتوسيع التخليص ، وتراجع الكفاءة.

- يانيس إصلاح: سرعات الحد الأقصى المدمجة في حدود آمنة (على سبيل المثال ، MAX 530 دورة في الدقيقة على مضخات YL87 MODEL).

blunder #2: علاج جميع السوائل نفس الشيء

ضخ الكاتشب بنفس سرعة زيت المحرك؟ خطأ كبير.

- اللزوجة مقابل القص: تحتاج السوائل عالية اللزوجة (مثل المواد اللاصقة) إلى سرعات بطيئة لتجنب التمزق. سوائل رقيقة؟ سوف ينزلقون الفصوص إذا كان بطيئًا جدًا.

- المذبحة في العالم الحقيقي: مقلية مصنع الجعة مضخة الملاط الخميرة عن طريق تشغيل 480 دورة في الدقيقة (يجب أن يكون 320 دورة في الدقيقة). النتيجة: 12 ألف دولار إعادة بناء.

- حركة ذكية: اختبار سرعات مع وحدة تجريبية يانيس VFD قبل الالتزام بالمخازن الثابتة.

blunder #3: رؤية النفق على دورة في الدقيقة وحدها

"لقد وضعنا 460 دورة في الدقيقة - Job Do!" (فشل في تحمل جديلة بعد 6 أشهر)

- السلسلة المخفية: تغييرات السرعة تؤثر على كل شيء في اتجاه مجرى النهر. مثال:

- ارتفاع دورة في الدقيقة ← المزيد من الاهتزاز ← ارتداء محمل سابق لأوانه ← فشل الختم ← التسرب

- لا تكذب البيانات: تُظهر بيانات حقل اليانيس أن 73 ٪ من "حالات الفشل المتعلقة بالسرعة" تنبع من الآثار الثانوية المتجلهة.

- للنصيحة: بعد ضبط دورة في الدقيقة ، شاشة:

- مستويات الاهتزاز (استخدم تطبيق هاتف ذكي بقيمة 20 دولارًا)

- تحمل درجة الحرارة (يجب أن تبقى <70 درجة مئوية)

- تسرب الختم (فحوصات مرئية شهرية)

خاتمة

ضبط سرعة مضخة الفص ليس علم الصواريخ - إنه أكثر ذكاءً من ذلك. يتعلق الأمر بالاستماع إلى السوائل ، واحترام حدود المواد ، واختيار الأدوات التي تتطابق مع شخصية سير العمل الخاصة بك. سواء كنت تختار مخفضات التروس التي لا معنى لها في Yaness أو الربيع لمرونة VFD ، تذكر: إن RPM المناسب اليوم يعني عدد أقل من الأعطال غدًا.

هل أنت مستعد لتحسين المضخة الخاصة بك؟

مضخات الفص المغلفة بالمطاط اليانيس مع المخفضات المدمجة ، توفر بساطة التوصيل والتشغيل للتطبيقات ذات السرعة الثابتة. [احصل على اقتباسك المخصص] الآن - لأن المضخات يجب أن تعمل من أجلك ، وليس العكس.