Boost Your Efficiency – Save up to 30% on Your Applications!

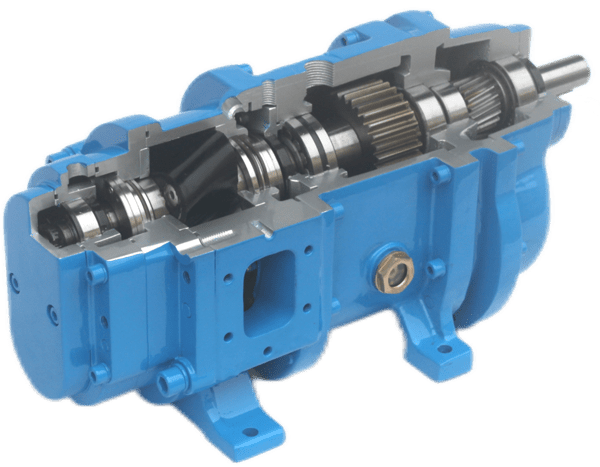

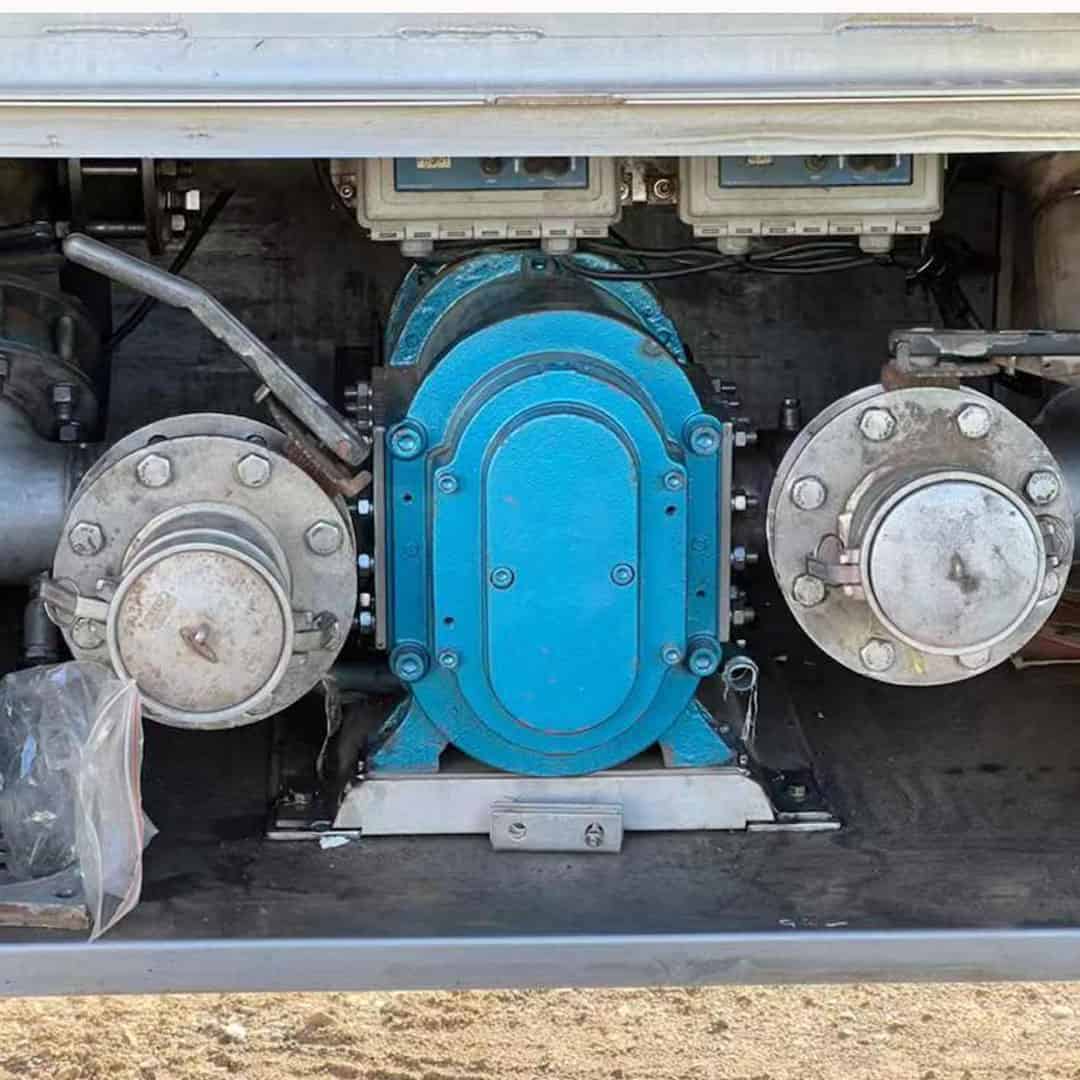

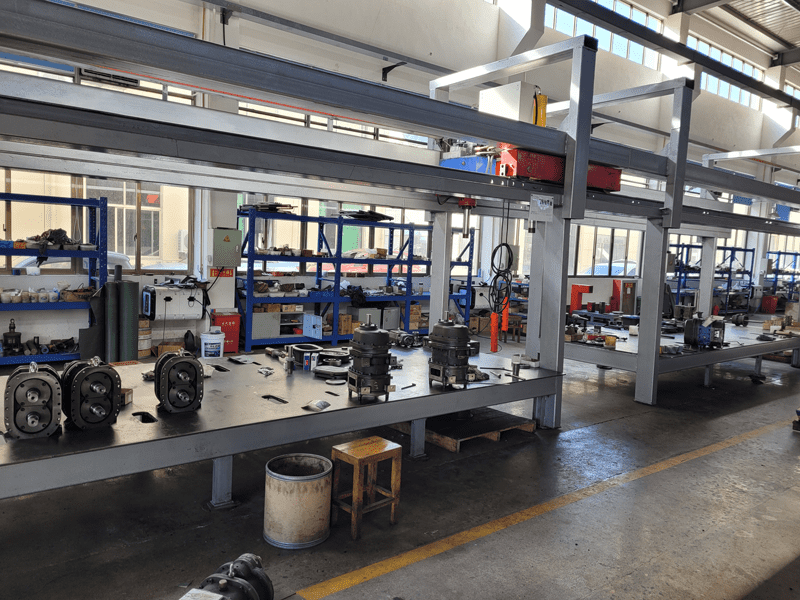

Leading Rotary Lobe Pump Manufacturer in China

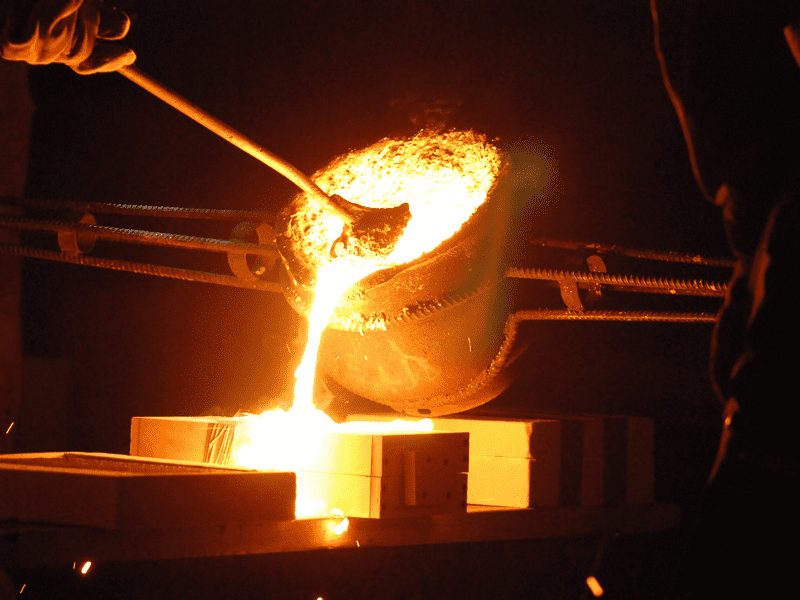

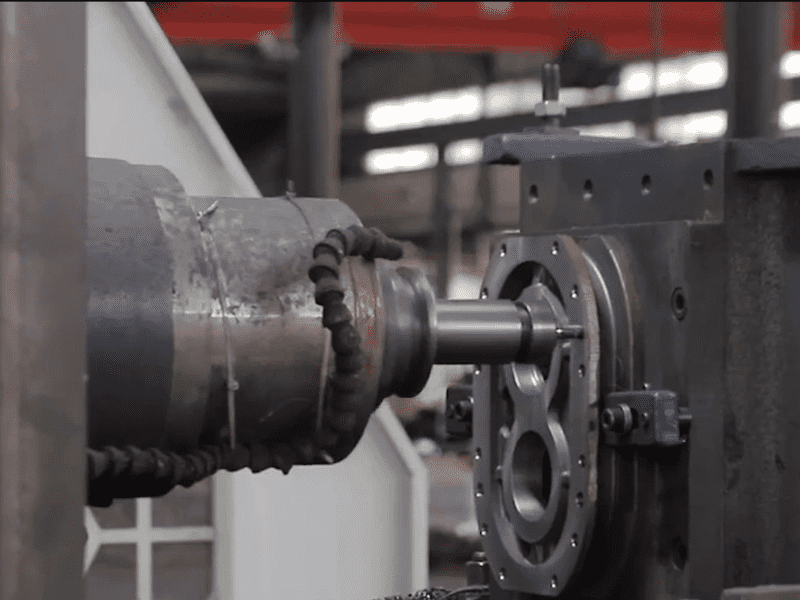

Yaness is a trusted manufacturer with years of experience providing top-quality Rotary Lobe Pumps for various industrial applications. Our pumps are designed to optimize your processes and maximize productivity. Get in touch today to receive a customized solution that meets your specific needs.